Copper Nickel Alloy

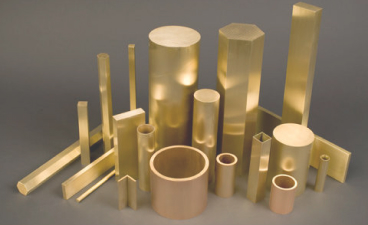

brass

Copper strip

copper plate

copper pipe

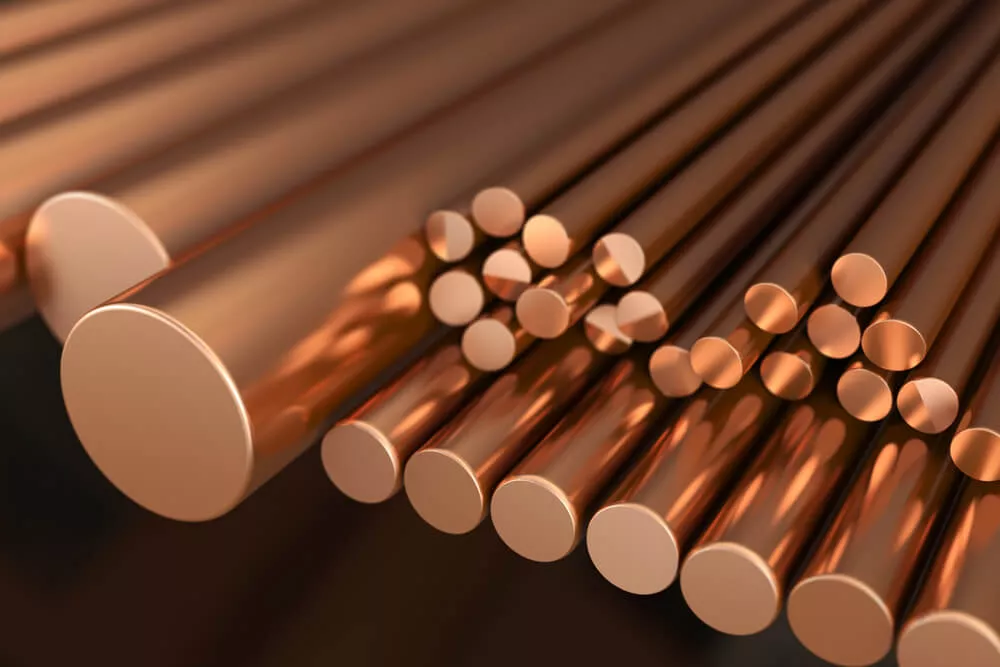

Bare Copper Wire Rods C1100

Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. The best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead.

The similarity in external appearance of the various alloys, along with the different combinations of elements used when making each alloy, can lead to confusion when categorizing the different compositions. There are as many as 400 different copper and copper alloy compositions loosely grouped into the categories: copper, high copper alloy, brasses, bronzes, copper nickels, copper–nickel–zinc (nickel silver), leaded copper, and special alloys.

| Family | Principal alloying element | UNS numbers |

|---|---|---|

| Copper alloys, brass | Zinc (Zn) | C1xxxx–C4xxxx,C66400–C69800 |

| Phosphor bronze | Tin (Sn) | C5xxxx |

| Aluminium bronzes | Aluminium (Al) | C60600–C64200 |

| Silicon bronzes | Silicon (Si) | C64700–C66100 |

| Cupronickel, nickel silvers | Nickel (Ni) | C7xxxx |

| Name | Nominal composition (percentages) | Form and condition | Yield strength (0.2% offset, ksi) | Tensile strength (ksi) | Elongation in 2 inches (percent) | Hardness (Brinell scale) | Comments |

|---|---|---|---|---|---|---|---|

| Copper (ASTM B1, B2, B3, B152, B124, R133) | Cu 99.9 | Annealed | 10 | 32 | 45 | 42 | Electrical equipment, roofing, screens |

| " | " | Cold-drawn | 40 | 45 | 15 | 90 | " |

| " | " | Cold-rolled | 40 | 46 | 5 | 100 | " |

| Gilding metal (ASTM B36) | Cu 95.0, Zn 5.0 | Cold-rolled | 50 | 56 | 5 | 114 | Coins, bullet jackets |

| Cartridge brass (ASTM B14, B19, B36, B134, B135) | Cu 70.0, Zn 30.0 | Cold-rolled | 63 | 76 | 8 | 155 | Good for cold-working; radiators, hardware, electrical, drawn cartridge cases. |

| Phosphor bronze (ASTM B103, B139, B159) | Cu 89.75, Sn 10.0, P 0.25 | Spring temper | — | 122 | 4 | 241 | High fatigue-strength and spring qualities |

| Yellow or High brass (ASTM B36, B134, B135) | Cu 65.0, Zn 35.0 | Annealed | 18 | 48 | 60 | 55 | Good corrosion resistance |

| " | " | Cold-drawn | 55 | 70 | 15 | 115 | " |

| " | " | Cold-rolled (HT) | 60 | 74 | 10 | 180 | " |

| Manganese bronze (ASTM 138) | Cu 58.5, Zn 39.2, Fe 1.0, Sn 1.0, Mn 0.3 | Annealed | 30 | 60 | 30 | 95 | Forgings |

| " | " | Cold-drawn | 50 | 80 | 20 | 180 | " |

| Naval brass (ASTM B21) | Cu 60.0, Zn 39.25, Sn 0.75 | Annealed | 22 | 56 | 40 | 90 | Resistance to salt corrosion |

| " | " | Cold-drawn | 40 | 65 | 35 | 150 | " |

| Muntz metal (ASTM B111) | Cu 60.0, Zn 40.0 | Annealed | 20 | 54 | 45 | 80 | Condensor tubes |

| Aluminium bronze (ASTM B169 alloy A, B124, B150) | Cu 92.0, Al 8.0 | Annealed | 25 | 70 | 60 | 80 | — |

| " | " | Hard | 65 | 105 | 7 | 210 | " |

| Beryllium copper (ASTM B194, B196, B197) | Cu 97.75, Be 2.0, Co or Ni 0.25 | Annealed, solution-treated | 32 | 70 | 45 | B60 (Rockwell) | Electrical, valves, pumps, oilfield tools, aerospace landing gears, robotic welding, mold making |

| " | " | Cold-rolled | 104 | 110 | 5 | B81 (Rockwell) | " |

| Free-cutting brass | Cu 62.0, Zn 35.5, Pb 2.5 | Cold-drawn | 44 | 70 | 18 | B80 (Rockwell) | Screws, nuts, gears, keys |

| Nickel silver (ASTM B122) | Cu 65.0, Zn 17.0, Ni 18.0 | Annealed | 25 | 58 | 40 | 70 | Hardware |

| " | " | Cold-rolled | 70 | 85 | 4 | 170 | " |

| Nickel silver (ASTM B149) | Cu 76.5, Ni 12.5, Pb 9.0, Sn 2.0 | Cast | 18 | 35 | 15 | 55 | Easy to machine; ornaments, plumbing |

| Cupronickel (ASTM B111, B171) | Cu 88.35, Ni 10.0, Fe 1.25, Mn 0.4 | Annealed | 22 | 44 | 45 | – | Condensor, salt-water pipes |

| " | " | Cold-drawn tube | 57 | 60 | 15 | – | " |

| Cupronickel | Cu 70.0, Ni 30.0 | Wrought | – | – | – | – | Heat-exchange equipment, valves |

| Ounce metal Copper alloy C83600 (also known as "Red brass" or "composition metal") (ASTM B62) | Cu 85.0, Zn 5.0, Pb 5.0, Sn 5.0 | Cast | 17 | 37 | 25 | 60 | — |

| Gunmetal (known as "red brass" in US) | Varies Cu 80-90%, Zn <5%, Sn ~10%, +other elements@ <1% |

| Family | CDA | AMS | UNS | Cu [%] | Sn [%] | Pb [%] | Zn [%] | Ni [%] | Fe [%] | Al [%] | Other [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Red brass | 833 | C83300 | 93 | 1.5 | 1.5 | 4 | |||||

| C83400 | 90 | 10 | |||||||||

| 836 | 4855B | C83600 | 85 | 5 | 5 | 5 | |||||

| 838 | C83800 | 83 | 4 | 6 | 7 | ||||||

| Semi-red brass | 844 | C84400 | 81 | 3 | 7 | 9 | |||||

| 845 | C84500 | 78 | 3 | 7 | 12 | ||||||

| 848 | C84800 | 76 | 3 | 6 | 15 | ||||||

| Manganese bronze | C86100 | 67 | 0.5 | 21 | 3 | 5 | Mn 4 | ||||

| 862† | C86200 | 64 | 26 | 3 | 4 | Mn 3 | |||||

| 863† | 4862B | C86300 | 63 | 25 | 3 | 6 | Mn 3 | ||||

| 865 | 4860A | C86500 | 58 | 0.5 | 39.5 | 1 | 1 | Mn 0.25 | |||

| Tin bronze | 903 | C90300 | 88 | 8 | 4 | ||||||

| 905 | 4845D | C90500 | 88 | 10 | 0.3 max | 2 | |||||

| 907 | C90700 | 89 | 11 | 0.5 max | 0.5 max | ||||||

| Leaded tin bronze | 922 | C92200 | 88 | 6 | 1.5 | 4.5 | |||||

| 923 | C92300 | 87 | 8 | 1 max | 4 | ||||||

| 926 | 4846A | C92600 | 87 | 10 | 1 | 2 | |||||

| 927 | C92700 | 88 | 10 | 2 | 0.7 max | ||||||

| High-leaded tin bronze | 932 | C93200 | 83 | 7 | 7 | 3 | |||||

| 934 | C93400 | 84 | 8 | 8 | 0.7 max | ||||||

| 935 | C93500 | 85 | 5 | 9 | 1 | 0.5 max | |||||

| 937 | 4842A | C93700 | 80 | 10 | 10 | 0.7 max | |||||

| 938 | C93800 | 78 | 7 | 15 | 0.75 max | ||||||

| 943 | 4840A | C94300 | 70 | 5 | 25 | 0.7 max | |||||

| Aluminium bronze | 952 | C95200 | 88 | 3 | 9 | ||||||

| 953 | C95200 | 89 | 1 | 10 | |||||||

| 954 | 4870B 4872B | C95400 | 85 | 4 | 11 | ||||||

| C95410 | 85 | 4 | 11 | Ni 2 | |||||||

| 955 | C95500 | 81 | 4 | 4 | 11 | ||||||

| C95600 | 91 | 7 | Si 2 | ||||||||

| C95700 | 75 | 2 | 3 | 8 | Mn 12 | ||||||

| 958 | C95800 | 81 | 5 | 4 | 9 | Mn 1 | |||||

| Silicon bronze | C87200 | 89 | Si 4 | ||||||||

| C87400 | 83 | 14 | Si 3 | ||||||||

| C87500 | 82 | 14 | Si 4 | ||||||||

| C87600 | 90 | 5.5 | Si 4.5 | ||||||||

| 878 | C87800 | 80 | 14 | Si 4 | |||||||

| C87900 | 65 | 34 | Si 1 | ||||||||

| † Chemical composition may vary to yield mechanical properties | |||||||||||