Катушка из нержавеющей стали 202

Катушка из нержавеющей стали 201

Катушка из нержавеющей стали 2507

Катушка из нержавеющей стали 310S

Дуплексная пластина из нержавеющей стали 2205

пластина из нержавеющей стали 201

Катушка из нержавеющей стали 904L

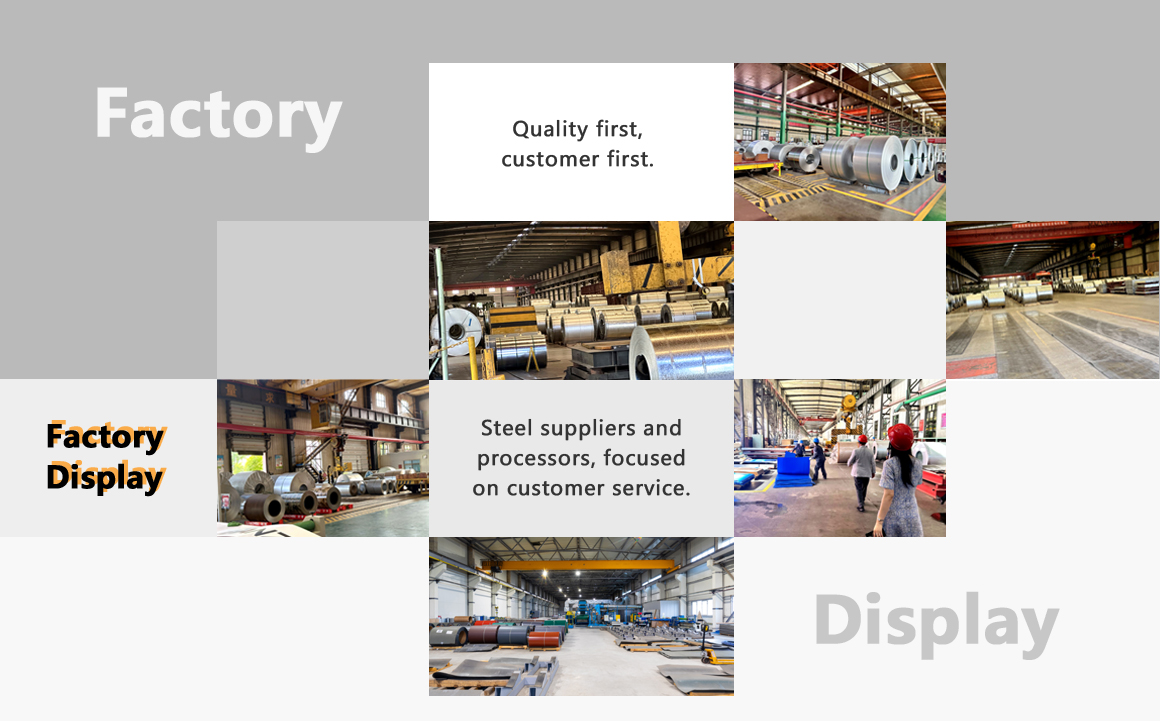

Наша рулонная продукция из нержавеющей стали имеет полный набор материалов и технических характеристик, а также выгодные цены. Предоставьте сертификат материала и отчет SGS.

Характеристики нержавеющей стали:

1. Полные характеристики продукта, разнообразие материалов;

2. Высокая точность размеров до ± 0,1 мм;

3. Превосходное качество и яркость поверхности;

4. Он обладает сильной коррозионной стойкостью, высокой прочностью на разрыв и усталостной прочностью;

5. Стабильный химический состав, чистая сталь и низкое содержание включений;

6. Упаковка хорошая и цена выгодная.

7. Его можно настроить.

Grade | 201/202/301/303/304/304L/316/316L/321/309S/310S/401/409/410/420J1 |

Surface Finish | 2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, ect |

Standard | JIS/SUS/GB/DIN/ASTM/AISI/EN |

Technique | Cold Rolled; Hot Rolled |

Thickness | 0.3-4mm cold rolled; 3-100mm hot rolled; Customized according to customer requirements |

Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

Length | 2000mm, 2438mm, 2500mm, 3000mm, 6000mm or as required |

Application | Interior/Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure;Shipbuilding |

Lead Time | Normally 7-15 working days after the receipt of 30% deposit, according to the quantity |

Payment Terms | 30% TT for deposit,70% TT /70% LC at sight balance before shipment |

Price Terms | FOB, EXW, CIF, CFR |

Packing | Standard Sea Worthy Package or according to customer's requirements |

Finsh | |

NO.1 | Hot-rolled surface,annealed and pickled |

NO.2D | Cold-rolled, an nealed and pick led without skinpassing |

NO.2B | The surface brightness and flatness of NO.2B is better than NO.2D. |

NO.3 | Polished with abrasive belt of grit #100#120,have better brightness with discontinuous coarse stria |

NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria |

HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks |

BA | Cold rolled, bright annealed and skin passed, the product has excellent brightness and good reflexivity like mirror |

Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

GB | RUSSIA | AISI、ASTM | JIS | BS | DIN | ISO |

1Cr18Ni9 | 12KH18H9 | 302、S30200 | SUS302 | 302S25 | X12CrNi88 | 12 |

0Cr18Ni9 | 08KH18H10 | 304, S30400、TP304 | SUS304 | 304S15 | X5CrNi89 | 11 |

00Cr19Ni10 | Z2CN18.09 | 304L S30403、TP304L | SUS304L | 304S12 | X2CrNi189 | 10 |

1Cr18Ni9Ti | X10CrNiTi189 | |||||

0-1Cr18Ni12Mo2 Ti | Z6CNDT17.12 | 320S17 | X10CrNiMoTi1810 | |||

00Cr17Ni14Mo2 | 03KH17H14M2 | 316Ls S31603、TP316L | SUS316L | 316S12 | X2Cr | 19、19 |

0Cr25Ni20 | 310S、S31008s TP310S | SUS310S | ||||

0Cr23Ni13 | 309S、 S30908 | SUS309S | ||||

0Cr17Ni12Mo2N | 316Ns S31651 | SUS316N | ||||

00Cr17Ni13Mo2N | Z2CND7.12N | SUS316LN | X2CrNiMoN1812 | |||

0Cr18Ni12Mo2Cu | SUS316JI | |||||

00Cr18Ni14Mo2Cu2 | SUS316JIL | |||||

0CM9NM9N | ZCNS18.09A2 | 304 | SUS304N |